A quality manual template is a structured framework for documenting policies, procedures, and processes to ensure compliance with standards like ISO 9001, supporting effective quality management systems.

1.1 Definition and Purpose

A quality manual template is a pre-designed document that outlines the structure and content for a company’s quality management system. It provides a framework for defining policies, procedures, and processes to meet ISO 9001 standards. The purpose is to ensure compliance, consistency, and effectiveness in managing quality across all operations, making it accessible and understandable for employees at all levels.

1.2 Importance in Quality Management Systems

A quality manual template plays a crucial role in establishing a structured approach to quality management. It ensures alignment with ISO standards, providing clear guidelines for operations and fostering a culture of continuous improvement. By standardizing processes, it enhances efficiency, reduces errors, and promotes compliance, ultimately contributing to customer satisfaction and organizational success.

Key Components of a Quality Manual Template

A quality manual template typically includes scope, structure, quality policy, objectives, roles, responsibilities, procedures, and forms to ensure comprehensive documentation and compliance with standards effectively.

2.1 Scope and Structure

The scope defines the quality manual’s applicability within an organization, while the structure organizes documentation logically. It typically includes sections like organizational context, quality objectives, roles, procedures, and forms. A clear hierarchy ensures easy navigation and compliance with standards like ISO 9001. The structure is customizable to meet specific industry needs, aligning with regulatory requirements and enabling efficient audits.

2.2 Quality Policy and Objectives

The quality policy outlines an organization’s commitment to quality, reflecting its mission and values. Objectives are measurable goals aligned with this policy, ensuring continuous improvement. Both elements guide decision-making and resource allocation, fostering a culture of accountability. They are integral to ISO 9001 compliance, as they define how quality is managed and achieved across all levels of the organization.

2.3 Roles and Responsibilities

Defining roles and responsibilities ensures accountability within the quality management system. Top management oversees strategy and resource allocation, while quality managers implement policies. Teams are tasked with executing processes, and employees adhere to standards. Clear roles foster collaboration, ensuring compliance with ISO 9001 and promoting a culture of continuous improvement and accountability across all organizational levels;

Benefits of Using a Quality Manual Template

Using a quality manual template ensures streamlined processes, compliance with ISO standards, and consistency across operations, enhancing efficiency and reducing errors in documentation and implementation.

3.1 Streamlined Documentation Process

A quality manual template simplifies documentation by providing pre-defined sections, reducing redundancy and errors. It aligns processes with ISO standards, ensuring consistency and clarity. Companies like Business Analytics LLC and Karelian Granite Company LLC leverage these templates to maintain organized records, facilitating compliance and efficiency in their operations. This structured approach saves time and resources, enabling focus on core business activities while meeting quality management requirements effectively.

3.2 Compliance with ISO Standards

Quality manual templates ensure alignment with ISO standards like ISO 9001-2015, providing predefined sections for policies, procedures, and documentation. This structured approach guarantees compliance by covering all necessary requirements, reducing errors, and streamlining audits. Companies like Business Analytics LLC and Karelian Granite Company LLC use these templates to maintain consistency and meet regulatory expectations, ensuring their quality management systems are both efficient and ISO-compliant.

How to Choose the Right Quality Manual Template

Selecting the right quality manual template involves ensuring ISO 9001 compliance, tailoring it to your business needs, and choosing a flexible format for easy customization.

4.1 Industry-Specific Requirements

Quality manual templates must align with industry-specific standards and regulations. For example, manufacturing may require ISO 9001 compliance, while healthcare might need additional safety protocols. Templates should be adaptable to meet these unique demands, ensuring relevance and effectiveness. By incorporating industry-specific language and requirements, organizations can maintain compliance and streamline their quality management processes efficiently. This tailored approach ensures the template remains practical and aligned with operational needs.

4.2 Customization Options

Quality manual templates offer extensive customization options to meet organizational needs. Users can tailor sections, add specific modules, and adjust language to align with industry standards. This flexibility ensures the template remains adaptable, allowing organizations to maintain compliance while reflecting their unique processes. Customization enhances relevance and usability, making the quality manual a practical tool for effective quality management across diverse industries and operational contexts.

Implementation and Maintenance

Effective implementation involves integrating the quality manual into daily operations, ensuring compliance with ISO standards. Regular reviews and updates maintain relevance and adaptability to organizational needs.

5.1 Training and Awareness

Training and awareness programs are essential for ensuring all employees understand the quality manual’s content and their roles within the system. Regular workshops and updates help maintain compliance with ISO standards, fostering a culture of quality and accountability across the organization. Continuous education ensures that staff are informed about changes and improvements, promoting active participation in quality management processes.

5.2 Regular Updates and Audits

Regular updates ensure the quality manual remains aligned with organizational goals and compliance standards like ISO 9001. Internal audits are conducted to assess the effectiveness of the quality management system, identifying areas for improvement. These processes maintain the integrity of the manual, ensuring it stays relevant and up-to-date with industry requirements and best practices, fostering continuous improvement and accountability within the organization.

Best Practices for Creating a Quality Manual

Best practices involve clear language, user-friendly design, and stakeholder involvement to ensure the manual aligns with ISO standards, fostering accessibility and compliance across the organization effectively.

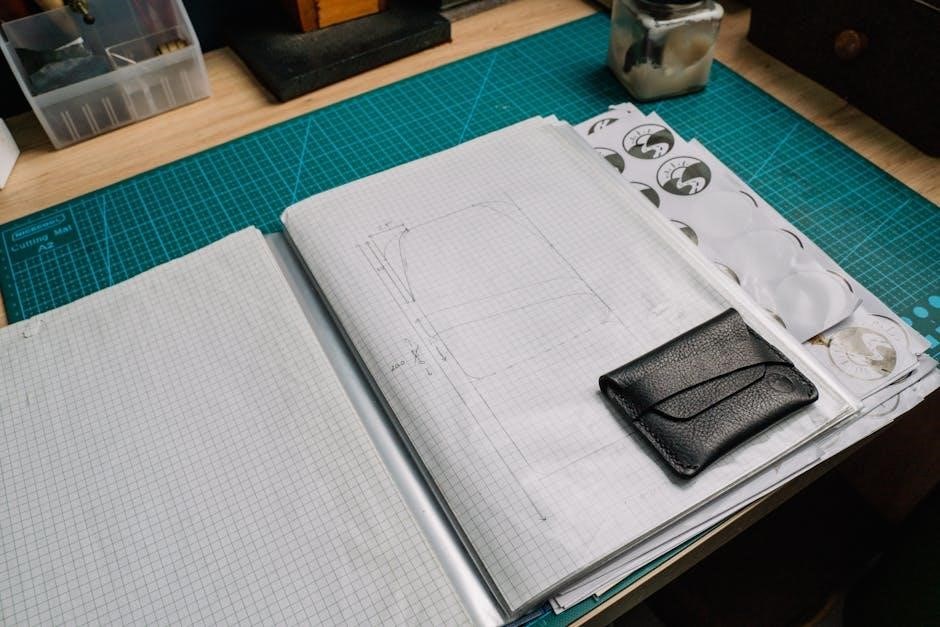

6.1 Clarity and Accessibility

Clarity and accessibility are essential for a quality manual to ensure all employees understand and follow procedures effectively. Using simple language, avoiding jargon, and organizing content logically are key. Incorporating visual aids like charts can enhance comprehension. Accessibility involves making the document easy to navigate with clear headings. Compliance with ISO standards requires that documentation is not only thorough but also understandable to all personnel, ensuring effective quality management across the organization.

6.2 Continuous Improvement

Continuous improvement ensures the quality manual evolves with organizational needs and industry standards. Regular audits and performance metrics help identify areas for enhancement. Aligning with frameworks like ISO 9001-2015 and GOST standards ensures adaptability. Companies like Business Analytics LLC and Karelian Granite exemplify this by integrating feedback loops and updating processes. This iterative approach fosters a culture of ongoing refinement, keeping the manual relevant and effective in maintaining quality management excellence.

Common Mistakes to Avoid

Common mistakes when creating a quality manual include non-compliance with industry standards, poor document clarity, and inadequate staff training, leading to ineffective quality management systems and potential audit failures.

7.1 Overcomplicating the Document

Overcomplicating a quality manual can lead to confusion and non-compliance. Avoid using overly complex language or unnecessary details. Ensure the document is clear, concise, and easy to understand. Focus on essential processes and procedures without adding redundant information. Use straightforward terminology and organize content logically. Regularly review and simplify the manual to maintain clarity and relevance, ensuring it remains a practical tool for your quality management system.

7.2 Lack of Employee Involvement

Failing to involve employees in developing a quality manual can hinder its effectiveness. Employees often have valuable insights into daily operations and potential improvements. Their involvement fosters a sense of ownership and ensures the manual is practical and relevant. Without employee participation, the document may lack real-world applicability, leading to poor implementation and reduced overall quality management system performance. Encourage collaboration to create a more effective and accepted manual.

A quality manual template is essential for effective quality management, ensuring compliance and continuous improvement while streamlining processes and fostering a culture of excellence within organizations.

8.1 Summary of Key Points

A quality manual template is an essential tool for establishing and maintaining a structured quality management system. It provides a clear framework for documenting processes, ensuring compliance with standards like ISO 9001, and aligning organizational goals with quality objectives. By offering customization options and industry-specific guidance, these templates streamline documentation, enhance employee involvement, and promote continuous improvement, serving as a foundation for effective quality management across all levels of an organization.

8.2 Final Thoughts on Effective Quality Management

Effective quality management relies on a well-structured approach, with a quality manual template as its cornerstone. By ensuring compliance with standards like ISO 9001, these templates help organizations maintain consistency, reduce errors, and foster a culture of continuous improvement. Ultimately, a commitment to quality management enhances operational efficiency, customer satisfaction, and long-term success, making it a vital component of any organization’s strategic framework.